True Seal 400S-PGIII | Concrete Sealer

True Seal 400S-PGIII | Concrete Sealer

Couldn't load pickup availability

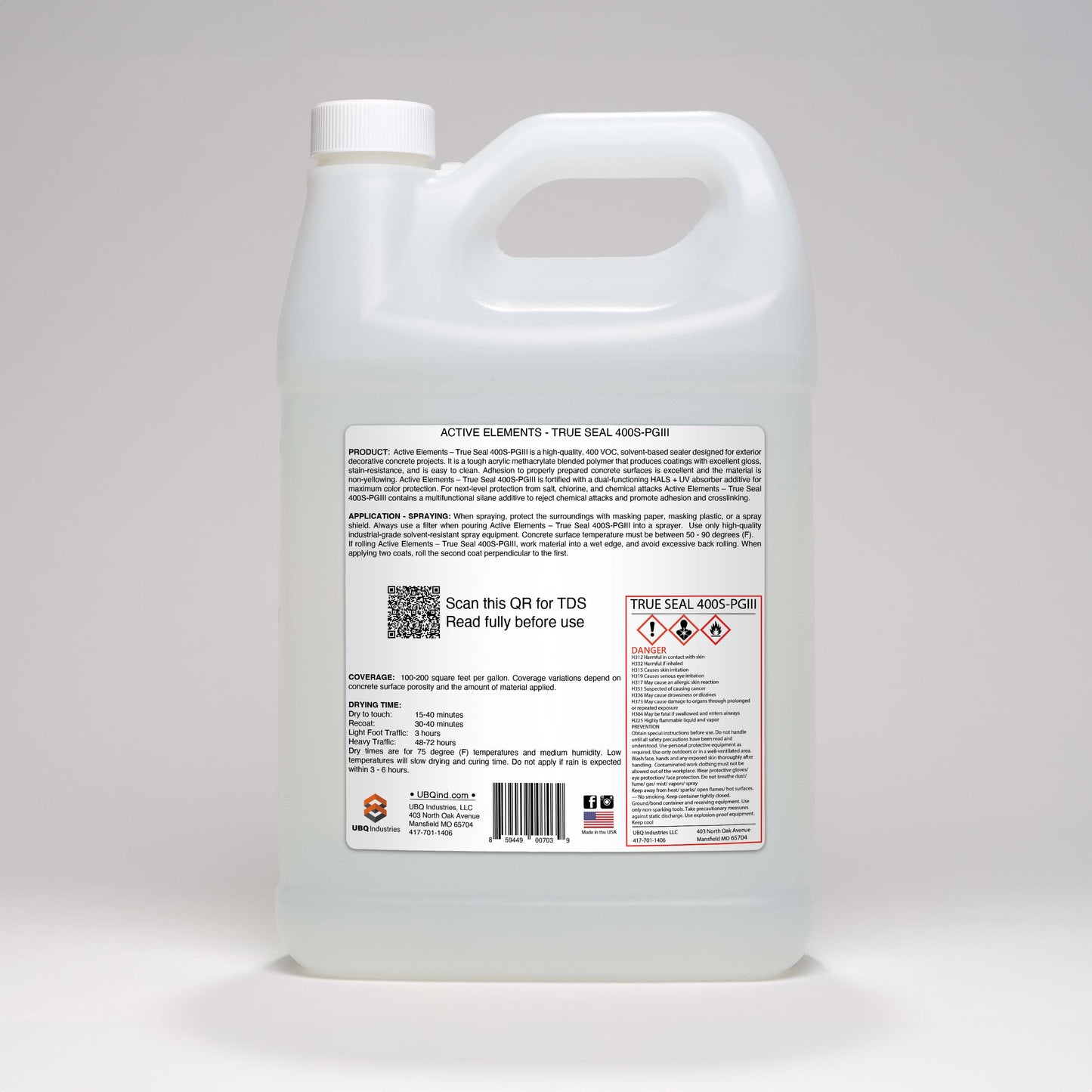

Active Elements – True Seal 400S-PGSIII is a high-quality, 400 VOC, solvent-based sealer designed for exterior decorative concrete projects. It is a tough acrylic methacrylate blended polymer that produces coatings with excellent gloss, stain-resistance, and is easy to clean. Adhesion to properly prepared concrete surfaces is excellent and the material is non-yellowing.

True Seal 400S-PGSIII is fortified with a dual-functioning HALS + UV absorber additive for maximum color protection. For next-level protection from salt, chlorine, and chemical attacks True Seal 400S-PGSIII contains a multifunctional silane additive to reject chemical attacks and promote adhesion and crosslinking.

KEY FEATURES

• Exterior Concrete Sealer

• Commercial, Retail, Residential

• Fortified with HALS + UV absorber

• Solvent Based

• Next level protection from salt, chlorine, and chemical attack

COVERAGE

100-200 square feet per gallon. Coverage variations depend on concrete surface porosity and the amount of material applied.

DRYING TIME

Dry to touch 15-40 minutes

Recoat 30-40 minutes

Light Foot Traffic 3 hours

Heavy Traffic 48-72 hours

Dry times are for 75 degree (F) temperatures and medium humidity. Low temperatures will slow drying and curing time. Do not apply if rain is expected within 3 - 6 hours.

SURFACE PREPARATION

Concrete must be clean and free of dirt, dust, oil, grease, mold, mildew, and any other contaminants. Acid-stained concrete must be neutralized, thoroughly cleaned, and dry prior to sealing. Pigment-stained concrete must be completely cured prior to sealing. All new concrete should be allowed to cure for a minimum of 28-45 days, or until a pH reading of 10.5 or less is achieved. Concrete must be completely dry prior to sealer application. It is strongly recommended that a surface probe moisture meter be utilized to verify the surface is dry. After visually determining the concrete is dry, test a minimum of 10 different areas of the concrete with the moisture meter. Pay special attention to cracks, control joints, and slab edges.

APPLICATION TOOLS

Pump sprayer, Airless sprayer, or Roller & Brush

SPRAYING (PREFERRED METHOD)

When spraying, protect the surroundings with masking paper, masking plastic, or a spray shield. Always use a filter when pouring True Seal 400S into a sprayer. Use only high-quality industrial-grade solvent-resistant spray equipment. Concrete surface temperature must be between 50 - 90 degrees (F).

ROLLING

Work material into a wet edge, and avoid excessive back rolling. When applying two coats, roll the second coat perpendicular to the first.

Review the tech data sheet (TDS) - pdf file (printable) before purchasing

Other products may be needed. The TDS will have that listed information.

Share